Good control of chemistry is essential to produce sound S.G Iron castings to the correct mechanical specification. Its well known that Magnesium treatment requires a certain quantity of residual Magnesium in the Iron along with low S' & O level.

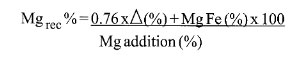

In general, a residual Magnesium range of 0.035-0.055% is required in the Iron considering whether its rapid or slow cooling rate to achieve full nodularity. Apart from Magnesium other supplementary additives are also used in the wire to achieve various metallurgical effects c.g. Ferrosilicon, Calcium Alloys, Cerium Misch Metal, and Carbon etc.

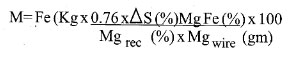

The computation of recovery is made from typical analytical results according to the following equation:

The Sulphur content before & after the Magnesium treatment, as well as Magnesium content in the iron must be determined. The Magnesium quantity added is known from Mg content (gm/m) of the respective Magnesium Cored wire & length injected (m).

The necessary quantity of Meltex Cored Wire is computed according to the following equation:

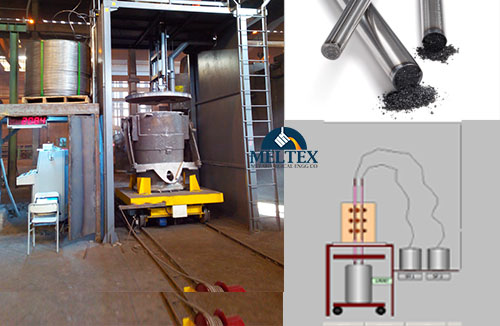

Meltex offers several wire compositions different application & are differentiated by the S-content of the base Iron. In addition Meltex offers customized wires based on special foundry requirement. Usually the wire diameters for Magnesium treatment are 9mm & 13 mm.